TECHNICAL NOTES SERIES

JOWETT JAVELIN – PA, PB, PC, PD & PE

PART XXI – MIDSHIP BEARING CONVERSION

THIS DOCUMENT HAS BEEN PREPARED SOLELY FOR PROVIDING TECHNICAL ADVICE

The Jowett Car Club of Australia Incorporated, although it developed this modification, is not responsible for any inaccuracies or changes that may occur within this document. Every effort has been made to ensure total accuracy. It is not a Jowett Car Club publication and, therefore, the Club has no control over its contents. These Technical Notes have been compiled by using the latest information available.

Compiled by Mike Allfrey – January, 2007.

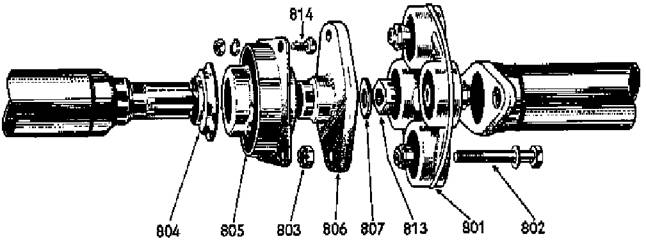

MIDSHIP BEARING CONVERSION KIT

Introduction

A number of years ago the genuine midship bearing assembly (AS50918) became impossible to obtain. The Jowett Car Club of Australia designed and developed a suitable conversion which is easily fitted by the car's owner. The conversion kit consists of the following individual components:

Part Number Description Qty In Kit

JK-50919 Aluminium Housing 1

JK-50918 Bearing (RLS-8) 1

JK-50924 Circlip (1300-57) 2

JK-50923 Seal (P3196) 2

JK-50917 Rubber Mounting 4

JK-50920 Nuts (8 mm) 8

Kit Installation

Note: Part numbers are shown in brackets after the description.

1. Park the car on a firm level surface.

2. Jack up the car and place suitable chassis stands to provide a suitable safe working height. If only two chassis stands are used, chock the front wheels and jack up the rear of the car.

DANGER! DO NOT WORK UNDER VEHICLE SUPPORTED ONLY WITH A JACK.

3. Release the handbrake, have gear shift in neutral.

4. Mark each component of the propeller shaft, with a white marker pen, so that shaft can be reassembled in correct alignment to maintain balance of the assembly.

5. Remove the centre Layrub coupling (50916). Place a support stand under the rear section of the propeller shaft (54106) to prevent damage to the rear Layrub coupling.

6. Remove the four bolts that secure the midship bearing to the cross-chassis support (52324).

7. Detach the front Layrub coupling at the gearbox companion flange (50120).

8. Rotate the front shaft (50324) until the midship companion flange (50927) lies in a horizontal plane and remove the shaft by drawing the flange through the opening in the midship bearing support (52324).

9. Remove the split pin from the slotted nut (FN410/K), or setscrew in early cars, and pull the companion flange (50927) from the propeller shaft. Do not forcefully clamp the shaft in a vice.

10. Using a press, or a suitable puller, remove the midship bearing (AS50918) from the propeller shaft.

11. IMPORTANT! Remove the dust slinger (50917) from the propeller shaft because it is not required with the new bearing.

12. Install one circlip (JK-50924) into a groove in the bearing housing (JK-50919).

Note:

The holes provided in the circlip, for the pliers, are tapered. Be sure to install the circlip with the pliers' prongs entering the smaller diameter of the holes, and, in this manner, install both circlips from each end of the bearing housing (JK-50919).

13. Using a sharp instrument, flick the protection seals out of the bearing (JK-50918) side faces.

14. Press the bearing (JK-50918) into the housing against the installed circlip (JK-50924) and install the second circlip to secure the bearing in the centre of the housing.

15. Press into position the two seals (JK-50923), with their 'open' sides towards the bearing.

16. Lightly pack the new bearing with multi-purpose grease, do not fill to capacity.

17. Apply a smear of multi-purpose grease to the seal lips

18. Press the assembled bearing housing on to the shaft, with the mounting flange facing the front end of the propeller shaft.

19. Thoroughly clean the companion flange, make sure that the grease fitting is in good condition.

20. Install the companion flange, taking note of the marks made at step 4. Tighten the slotted nut to 60 lb. ft. and, if necessary, tighten further to install a new split pin. Or on early cars, tighten the setscrew to 28 lb. ft. against a new spring washer.

21. Replacement of the shaft assembly into the car is the reverse of the removal procedure given above.

22. NOTE: The four rubber mounts (JK-50917) are fitted between the bearing housing flange and the front face of the cross-chassis midship bearing support (52324). Secure the nuts with spring washers.

23. At 5,000 mile intervals, apply two shots of multi-purpose grease. Do not over grease this bearing assembly.