Introduction

The engine cooling system for the Jowett Javelin and Jupiter motor

cars are very similar and, for convenience here, they are termed 'the Jowett

engine' cooling system. When Jowett Cars Limited wrote their Specification

Notes for the Jowett engine cooling system, the system was described as being

of the 'thermo-siphon' type – assisted by a water pump. Until the advent of the

Javelin saloon and the Jupiter roadster, all Jowett vehicles featured cooling

systems of the thermo-siphon type. It has been frequently stated that the water

pump installation on the Javelin was an afterthought. The same could be said

about the Jupiter's water pump installation, but it has been engineered just

that much better than its sibling.

It is true that the system is assisted by a water pump. The engine

cooling system, as applied to the Javelin and Jupiter, is not of a common type.

The following departures from convention can be noted:

1. The

radiator is mounted to the rear of and above the level of the top of the

crankcase.

2. The

water pump pushes hot water into the radiator's header tank . Most other

manufacturers' systems have the pump pushing cooled water into the cylinder

block.

3. There

are two bottom hoses, one for each cylinder bank.

4. On

the Javelin there is a single, centrally located top radiator feed.

5. On

the Jupiter there is also a single, centrally located top radiator feed that

branches into two to feed each end of the radiator header tank.

6. The

Javelin was one of the first cars to feature air shroud/duct plates for the

cooling fan.

7. The

engine cooling system is serviced by two drain taps, one in each cylinder head.

The radiator, being the highest point in the system, does not require a drain

tap.

Even with all of these differences, the Jowett engine cooling system

will, if properly maintained, function very well.

History

Throughout the engine cooling system's production life, detailed

improvements were introduced. These are best summarised as follows:

1. Air deflectors for the fan were changed to increase the

efficiency of air flow. The change related to a curved edge section adjacent to

the cooling fan's arc.

2. The

water pump front cover was improved by introducing a shroud to better hold

water in the impellor until it was time to be discharged to the thermostat

housing and on to the radiator (D9 PA 5756).

Note:

All Club manufacture front covers feature the cast-in shroud. It is now rare to

find a pump with the early front cover installed.

3. The

fan shaft and rear bushing were increased from 0.500" (12.70 mm) diameter

to 0.625" (15.875 mm) diameter. The fan boss retained the ½" BSF

threaded mounting centre and lock nut.

4. The

fan shaft and fan securing changed to a taper fit with a self locking (Simmons)

nut and plain washer.

5. Following

difficulties in service when removing the fan from the shaft due to taper lock,

a revised taper specification was introduced.

6. The

original fan was of the St Andrew's cross type, with ½" BSF threaded

mounting.

7. A

fan of the St George's cross type with ½" BSF threaded mounting.

8. A

fan as in 7., but with first taper mounting.

9. A

fan as in 7., but with revised taper mounting (E2 PD 20379).

10. A

pressed brass sheet shroud silver soldered or riveted to machined front face of

water pump impellor.

11. Changes

to lubrication methods for fan shaft.

12. Introduction

of improved radiator for Jupiter.

All available Jowett Cars Limited issued Service Bulletins relating

to the engine cooling system are reprinted from Page 7 of this document..

Engine Cooling System Maintenance

Just like any other mechanical component in a motor car, the engine

cooling system can, with great usage and neglect, become worn and tired. This

is particularly so in modern times. It is a fact that most Jowett engines are

now running in a hotter state than was known some fifty years ago. There are

several reasons for this condition, which will be dealt with later.

Hoses

With higher operating temperatures and the banning of some chemicals

that used to be used in the manufacture of rubber hoses, engine cooling system

flexible hose life is reduced somewhat. Ideally, and to provide peace of mind,

the hoses in the cooling system should be changed every two years. Radiator

hoses can suffer due to engine coolant having too strong a corrosion inhibitor

or anti-freeze mixture. If a glycol based anti-freeze is of to great a proportion

of the coolant mix, the hoses will become very soft and will de-laminate.

De-lamination is the term used to describe the separation of the

inner hose liner coming away from the reinforced part of the outer hose. In

severe cases, a water pump can exert sufficient suction to collapse the inner

liner, thus restricting coolant flow. This condition may not be easy to diagnose,

but if the hose suddenly feels softer, this is a fair indication that

de-lamination has occurred.

A coolant hose should be a snug fit on the attaching

barbs/pipes/housings. It should be of sufficient length to accommodate its

securing clamps.

Hose Clamps

There are a number of different style hose clamps available, but

care must be exercised when choosing a clamp. Most clamps are of the worm drive

type. There are many variations on this theme. Some, that are made from very

thin stainless steel, have a coarse pitch worm drive to tighten them. These

hose clamps can, if over tightened, twist to the extent that the rubber outer

wall of the hose can be severely cut. Too often, such hose clamps can be seen

with the rubber projecting through the worm slots.

The original wire type of clamp that was used by Jowett Cars

Limited, if used as it should be, is a very effective clamp. There is also a

very good quality, non-worm drive, clamp made by Würth

of Germany. These clamps can be found at swap meets. The band of the clamp has

a generous radius at each side, thus being gentle on the rubber hose. The smaller diameter Würth clamps are, in

some cases, the only clamp authorised by vehicle manufacturers for fuel

injection hose use.

Hose Installation

There is a technique that should be adopted when installing any new

hose. A new hose should be installed onto clean, corrosion-free, hose barbs.

The hose clamp should be located to the immediate rear of the raised portion of

the hose barb. When installed, the hose itself should be in a relaxed

condition. Only use genuine hoses which can be supplied by the Jowett Car Club

of Australia Inc.

Engine Coolant

To avoid corrosion within the cooling system, it is wise to use a

suitable corrosion inhibitor. For the Javelin and Jupiter engine, which contain

several different metals that make up the cooling system, it is recommended

that a good quality corrosion inhibitor such as Tectaloy Xtra Cool Gold, which

meets AS2108 2004 B. This is a concentrated formula and one litre will make up

fifteen litres of coolant. Add the contents of a one litre bottle to fourteen

litres of soft water, fill the engine cooling system and keep the remainder for

top-up purposes. This ensures that the original mix is not diluted. Tectaloy

Xtra Cool Gold can remain in the cooling system for three (3) years or 37,000

miles, whichever occurs first.

Ford R1-3B Corrosion Inhibitor can also be used in a mix by volume

of 10% R1-3B and 90% clean soft water. This mixture should be drained, flushed

out and replaced with new mixture at two year intervals.

It should be noted that these inhibitors are not an antifreeze type

inhibitor. If using the motor car in sub-zero temperature, taking into account

wind chill factor, conditions, then a propriety type of antifreeze-inhibitor

should be used at recommended strengths.

The coolant mixture needs to be used with extreme care. The balance

between protection and damage is a very delicate chemical specification. Too

little inhibitor will mean corrosion problems at the aluminium components. Too

much inhibitor in the mixture will result in solder bloom problems in the

radiator.

For maximum cooling efficiency, the coolant and cooling system

internal components must be kept absolutely clean.

Perceived High Running Temperatures

Most ‘overheating’ concerns are, in most cases, perceived concern.

This statement needs clarifying.

The Jowett Javelin and Jupiter models are equipped with temperature

gauges that provide reasonably accurate readings between 30°C to 100°C. The temperature gauge provides information that can be interpreted

by the driver. A modern car's temperature gauge that typically displays Cold –

Normal – Hot does not provide specific information, and the 'Normal' segment

can be covered by a large arc of the indicator needle.

The question needs to be asked – What is the 'Normal' operating

temperature for the Jowett engine?

Most are aware that 75°C can be considered to be the normal operating temperature, simply

because it is located at mid-point on the gauge scale. Fair enough. Others know

that the engine is equipped with a 75°C opening thermostat and, therefore, the 'normal' operating

temperature is 75°C. again, a

fair assumption can be made.

That is all very well, but care needs to be taken when interpreting

the 'normal' operating temperature.

Consideration needs to be given to the following points:

1. The cooling system's design criteria probably allows for 'normal'

reading at ambient temperatures in the range of – 10°C to + 25°C.

2. If the ambient temperature is higher than 25°C, then the cooling system will operate at a proportionately higher

'normal' operating temperature. This higher operating temperature can be as

high as 87°C, providing the

engine and its cooling system are in good condition, without any cause for

alarm.

3. Accumulation of dust, oil, insects and other debris on the engine

and radiator will cause higher operating temperatures.

4. Excessive thickness paint on a radiator will form a very good

insulation layer.

5. Scale inside an engine's cooling system also forms an excellent insulator.

6. It is possible that modern petrols do burn (combustion) at higher

temperatures.

7. In metropolitan areas, modern traffic conditions cause the engine to

be running at low-idle for long periods with minimal air flow through the

radiator core. In this situation, should the operating temperature drop back to

'normal' once out on the open road, there is nothing inherently wrong with the

cooling system.

8. A slipping fan belt can cause high operating temperatures. The drive

belt should be wedged in the pulley Vee, if running in the bottom of the Vee,

the belt will slip.

9. Wind direction can have an effect on operating temperatures.

Javelins can be affected more if the wind is from one side than from the other

side.

10. Removing

the thermostat to effect a cure for a perceived overheating concern is not a

recommended practice.

JOWETT CARS LIMITED SERVICE BULLETINS –

COOLING SYSTEM

Bulletin Issue Date: March 1950

Item No. 5. Cooling System

Agents will of course be aware

that with a pressurised cooling system it is essential that the radiator cap is

removed when draining, in order to ensure that the system is completely empty.

Some owners may not,

however, be aware of this and we would therefore strongly recommend that you

emphasise to such owners the importance of carrying out the following drill

when draining:

1. Remove the radiator cap.

2. Open drain taps under cylinder heads and check that water is flowing

freely.

3. As soon as all water is drained from the cooling system, run the

engine for NOT more than 10 seconds.

Bulletin Issue Date: April 1950

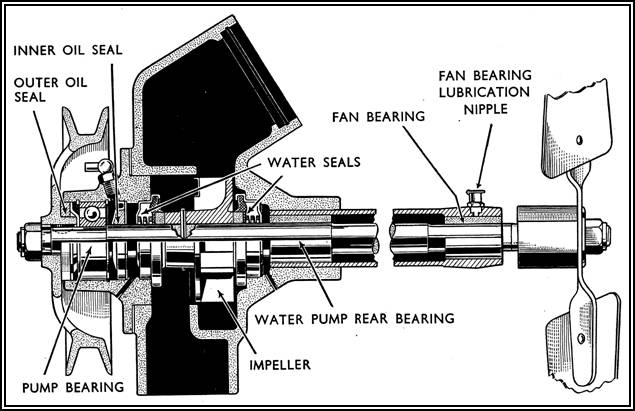

Item No. 14. Water Pump Housing

From Engine Number E0 PB 8472 an

oil cup has been fitted to the rear of the water pump housing extension tube to

assist the lubrication of the fan bearing.

Refer to Spares Note

Number 28 for parts change information.

Bulletin Issue Date: October 1951

Item No. 61. Overheating – PC Models

There is a possibility that a

number of Bowman manufactured radiators as fitted to Javelin Cars between

approximately Engine Number E1 PC 15910 and E1 PC 17545 have had an excess

thickness of paint applied to the radiator tubes. If under normal working

conditions (not exceptionally hot and sunny days) a thermometer reading in

excess of 81°C is registered,

action should be taken to check the following points:

1. Incorrect ignition timing or faulty action on the automatic

advance and retard mechanism

2. Loss of water.

3. Temperature gauge registering incorrectly.

4. Incorrect Carburettor adjustment.

5. Brakes binding.

6. Thermometer sticking.

7. Fan belt slipping.

8. Blockage in cooling system.

9. Incorrect valve timing.

10. Dash side air vent blockage.

11. Is the mileage and engine performance sufficient to indicate

that a decarbonising service is required?

12. Fan blade angle incorrect.

In the event of the above points

having been checked and found correct and overheating is still experienced,

attention should be focussed on the radiator assembly. If the radiator fitted

to the car is of Bowman manufacture, which may be identified by a plate fitted

to the front of the header tank stamped 'Bowman Birmingham Ltd.', it will be necessary

to take the following action:

1. Remove the radiator block and immerse it in thinners until the

paint on the honeycombing is loosened and peels away.

2. Remove the block from the thinners and direct a medium force of

water through the honeycombing to dislodge any particles of paint which may

still adhere to the tubes, and also neutralize the thinners action.

3. Follow this by blowing through the honeycombing with a strong

jet of air to remove any paint sediment which may be trapped in the

honeycombing.

4. Allow the block to dry and apply a very thin coat of protective

paint to the honeycomb and radiator body.

Note: Where vehicles are operating

in countries where a high ambient temperature is normally experienced, the thermometer

temperature reading will be correspondingly higher than the normal running

temperature of approximately 75 °C and in these cases the above action should only be taken when

normal running temperatures above 87½ °C are registered.

Bulletin Issue Date: October 1951

Item No. 65. Water Pump Modification – PC Models

From Engine Number E1 PC 18140, an

improved type water pump and fan assembly, which embodies the following

modifications has been introduced:

a) Single pressing fan with a taper fitting to the water pump

spindle.

b) A slip ring fitted to the water pump impellor to increase

circulated volume.

c) The internal diameter of the rear fan spindle bearing, Part

Number 50600, has been increased to give additional bearing surface.

d) Threaded studs on the fan spindle bearing housing for the

fitting of the fan support struts with the use of 'Oddie' nuts.

Note: To allow a certain amount of flexibility on the water

pump supporting stays, the 'Oddie' nuts must not be tightened fully down.

The following parts on the new

assembly are not individually interchangeable with corresponding parts on water

pumps prior to Engine Number E1 PC 18140, and stocks of these parts will be

maintained by our Spares Department for servicing requirements:

1. Water Pump Housing (Part Number J54505)

2. Water Pump Spindle (Part Number 54331)

3. Rear Fan Spindle Bearing (Part Number 50600)

4. Fan Assembly (Part Number 53058)

The new type pump, Part Number

J54513, complete with fan assembly is fully interchangeable with the previous

type as a complete unit.

For parts change information

please refer to Spares Note Number 80.

Bulletin Issue Date: March 1952

Item No. 85. Water Pump and Fan – Javelin and

Jupiter

Further to Bulletin Item Number

65, from Javelin Engine Number E2 PD 20379 and Jupiter Engine Number E2 SA 575,

a non stick taper has been introduced to the water pump spindle to facilitate

the removal of the fan. This modification incorporates a sharper taper at the

fan location end of the spindle. The new type fan and spindle are fully interchangeable

as a pair with the types previously fitted, but not as individual items.

For parts information please refer

to Spares Note Number 100.

Bulletin Issue Date: May 1952

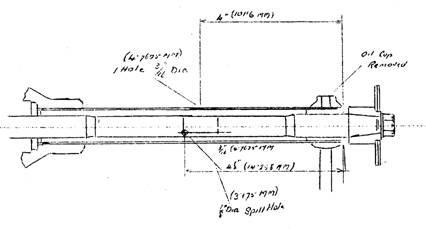

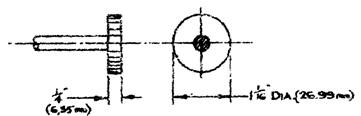

Item No. 93. Lubrication of Fan Spindle Bearing –

Javelin

With the introduction of the

radiator mounted oil cooler the fan support tube oil cup, Part Number J54011,

was inaccessible and therefore removed. A 3/16" (4.7625 mm) hole is now

incorporated in the fan support tube for lubrication purposes together with a

1/8" (3.175 mm) spill hole to prevent over lubrication.

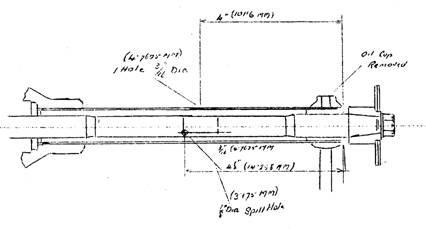

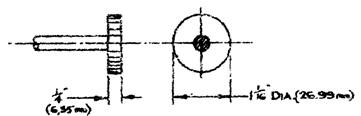

Figure 1. Dimensions for drilling fan support tube.

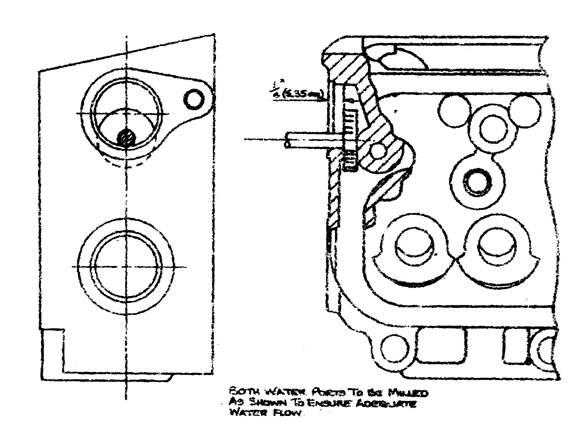

Bulletin Issue Date: November 1953

Item No. 163. Engine Overheating and Pinking – Javelin

and Jupiter

Cases have occurred where engine

overheating and pinking has been caused by a restriction between the outer wall

of the cylinder head and the cylinder head stud hole casting shown in Figure 1.

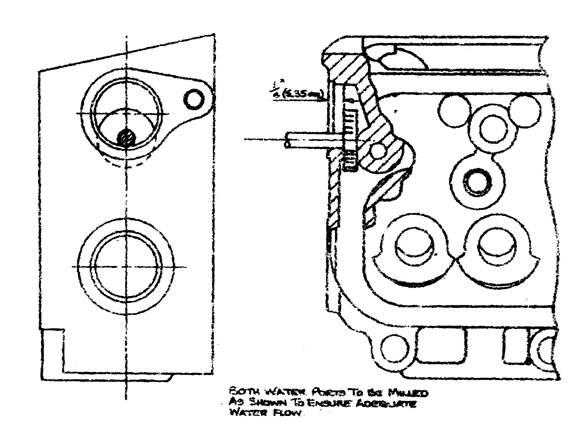

Figure 1. Showing where material can be milled from cylinder head.

In cases of this nature an

adequate water flow between these two points can be ensured by inserting a

Woodruff cutter as shown in Figure 1 through the cylinder head water port,

Figure 1, and milling a ¼" (6.330 mm) passage between the cylinder head outer

wall and the stud hole casting.