Introduction

These notes have been prepared using information sourced from the

Jowett Car Club of New Zealand. The modifications described herein are designed

to bring an early style oil pump to, as close as possible, the final

specification of oil pump used in the Jowett Series III engine. These changes

have not been designed to increase engine performance, although they do influence

the durability aspect to some degree.

Jowett Cars Limited found that engine oil delivery to vital

components, could be significantly increased without having to increase the

size of the pumping elements. It was found that by the simple medium of increasing

the size of oil delivery galleries, and the oil suction pipe, oil flow to the

crankshaft bearings was increased. These notes describe how increased flow can

be achieved with an earlier style oil pump assembly/

The Oil Pump’s Development

Initially, in the very early Jowett Javelin motor car, the oil pump

did have a smaller pumping element. The two gears were shorter, and had the

same part number 50668. The very early pumps can best be identified by the

brass oil pump cover and filter assembly, with part number 50674. The brass

pump cover is not recommended for use for these reasons:

- The pressure release valve spool wears at the valve bore in the

housing.

- The brass body can bend due to the weight of the oil pick-up

assembly.

- The shorter pump element gears and corresponding body are not

as efficient as the later type pumps.

- The pump element gears cause wear at the pump cover and become

less efficient.

The next style pump has the longer pump element gears and body to

match them. The gears have two part numbers, 52347 and 52348 The pump cover was

made from cast iron and it also was equipped with a non-adjustable relief valve.

This pump carried over the same size suction and delivery pipes as previously.

The final style pump featured several changes:

- The pump body was lengthened to bring the pumping element

portion closer to the engine oil level for quicker oil pick-up.

- The oil pressure release valve featured a larger diameter

spring.

- The oil pressure release valve was adjustable, using a threaded

spring cap with a lock nut.

- The oil exhausting back to sump was directed to exhaust into

the pump’s suction port. The reason for this change was to minimize

aeration of the exhausted oil

- The diameter of the suction pipe was increased.

- The delivery pipe’s diameter was increased.

- The deeper pump body required a longer drive spindle.

- The deeper pump body required a longer Idler spindle.

It is commonly believed that the Series III oil pump was equipped

with longer pump element gears – this is most certainly not the case.

A number of both later style oil pumps can be found with a pair of

drive-gear pumping element gears.

The Jowett engine oil pumps can best be described here as Types I,

II and III. These identifying types have been used in these notes for

convenience. The subject of these Technical Notes is to describe the modifications

to the Type II pump and its delivery system.

It should be appreciated that the engine, for which the pump is

being modified, should be completely dismantled so that these modifications,

which will only work if the crankcase and rear timing cover are also modified,

it is the total modification that works in harmony.

To Modify The Type II Pump

1. The

pump must be completely dismantled and properly washed before work commences.

2. Using

the bronze welding process, build up the oil pump body in the area forward of

the delivery pipe banjo threaded hole.

NOTE:

This area has to be built up sufficiently to accommodate a suitable sealing

washer.

3. Set

the oil pump body up in a milling machine and, using the ½” threaded hole as a

pilot, spot face the seal washer seat area. Drill the hole out to tapping size

for either the Jowett 5/8” thread, or to take a 16 mm thread. This depends on

the banjo bolt being used. Check the thread pitch on the banjo bolt being used.

NOTE:

Jowett Cars Limited used a non-standard thread pitch for the larger banjo bolt.

The New Zealand club have had a tap specially made for this purpose.

4. Trial

fit the delivery pipe banjo, sealing washers and bolt to check that the bottom

of the bolt can not possibly clash with the pump element gears.

5. If

a clash condition exists, the banjo bolt will require shortening in a lathe.

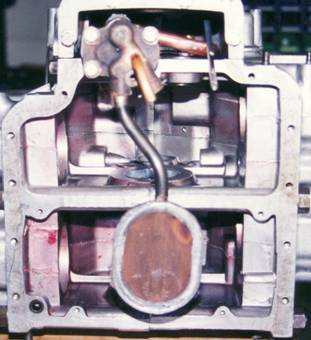

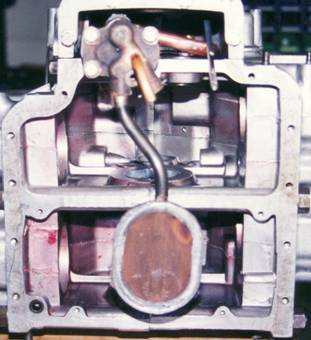

Figure 1: Oil pump body modification,

6. Drill

locking wire holes through the corners of the banjo bolt’s hexagon. Remove any

burrs.

.

Modifying The Cover And Filter Assembly

7. Cut

the suction pipe away from the cover plate.

8. Drill

out the cover plate to snugly accept the larger diameter suction pipe. This

should be of 5/8” nominal bore.

9. Make

sure that all hacksaw and drilling burrs are removed.

10. Cut

the suction pipe out of the strainer assembly.

11. While

the new pipe is still straight, set up in a milling machine and mill a larger

intake slot as per the original pipe. Weld a blanking plate over the end.

12. Bend a new steel suction pipe so that it holds the strainer approximately 8 mm above the

inside face of the engine oil sump.

13. Using

the bronze welding technique, tack weld the components together and, if

necessary, fine tune them into position. Complete the welding process.

NOTE:

After welding it is advisable to ensure that the joints are sound and no air

can be sucked in.

14. If

required, install a new strainer gauze.

15. Out

of 3/8” nominal bore copper tube, form an elbow with a minimal radius, but keeping

the inner bore cross sectional area. This elbow is positioned over the excess

oil exhaust port and should direct the return to sump oil rearwards below

normal oil level.

16. The

elbow should be silver soldered directly over the exhaust port. Care should be

taken to ensure that no solder enters the oil pressure release spool bore. The

spool should be checked for free travel along its entire bore in the cover.

17. Thoroughly

was the cover and filter assembly.

18. Check

that the pump body contact surface is perfectly flat. If any distortion has

taken place, surface grind the surface absolutely flat.

19. Wash

the cover assembly, the release valve spool, spring and its keeper. Lubricate

the parts with clean engine oil. Assemble these components into the cover and

fasten with a hardened split pin.

20. Place

the assembly in a plastic bag for storage.

Modifying The Oil Delivery Pipe

Figure 2: A steel banjo fitting.

21. When

improvements are made to the suction side of the oil pump, they have to be

followed on the delivery side. This can be done quite easily by using a ½” bore

(nominal) copper tube. A larger banjo fitting, as shown in Figure 2, can be obtained

from a supplier of hydraulic fittings.

Modern Banjos come with

hose barbs and are made from steel that has been zinc plated.

22. Cut

the barbs off at the banjo outlet boss.

23. Enlarge

the outlet bore to 11 mm diameter.

24. The

copper tube should fit over the outlet boss.

25. Remove

the original delivery pipe from the oil delivery elbow.

26. Drill

out the inlet and outlet passages to provide an 11 mm diameter oil passage

through the elbow.

27. Make

sure that the copper tube fits over the inlet boss of the elbow.

28. Bolt

the elbow to the front of the crankcase.

29. Install

the modified oil pump body on to the crankcase. Make sure that it is in its

fully home position on both dowels.

30. Bend

the annealed copper tube to follow the shape of the original delivery pipe, and

so that the new pipe sits close to the front face of the crankcase.

The

new pipe should be fitted over the bosses on the banjo and the delivery elbow.

NOTE:

Caution needs to be taken – the very early engines had delivery elbows that had

different bolt orientation. Make sure the pipe is being fabricated on the same

style crankcase as that being used for the modified pump assembly.

31. Make

sure that the banjo fitting at the pump is mounted on its sealing washer and

the bolt is tight.

32. Before

silver soldering the two joints, ensure that there is clearance for the timing

chain. The final lay of the pipe should be the sane as shown on the front cover

of this booklet.

33. Once

the pipe and fittings have been silver soldered, the assembly should be allowed

to cool. The pipe assembly can then be removed and tested for leaks using water

and compressed air.

Check

also that the jet orifice, that directs oil to the timing chain, is still

clear.

34. The

pipe assembly should be thoroughly washed and have any soldering flux residue

removed.

Modifying The Crankcase

The oil path beyond the oil delivery pipe elbow should also be

modified. This requires that the LHS half of the crankcase to be mounted in a

suitable drill press;

35. Drill

the inlet gallery to 11 mm diameter. This is a straightforward 90° to the face drilling exercise. Do not

drill deeper into the crankcase.

36. Set

the crankcase half up on the drilling table so that a drill the size of the

original outlet to the filter gallery passes, freely up and down as the handle

of the drill is actuated. Remove this drill from the chuck and install an 11 mm

diameter drill.

NOTE:

Because the drilling is at an angle to the surface of the crankcase, where the

rear timing cover sits, it is advisable to use a short drill, It is a good idea

to have a larger diameter centre-drill ground to 11 mm diameter to achieve a rigid

drill bit for this operation.

37. Using

the same method, the two galleries that enter the longitudinal galleries, can

be enlarged to 8 mm diameter.

NOTE:

Extreme care needs to be taken here. There is a possibility that these

drillings are very close to the attaching setscrew threaded holes. If this is

the case, the galleries can be counter-bored and aluminium plugs pressed in The

centres for the galleries can be marked out further away from the threaded

holes and then re-drilled with an 8 mm diameter drill.

Modifying The Rear Timing Cover

During

the Jowett engine’s production life, there were three different rear timing

covers. The earlier filter, known as the Vokes oil filter is easiest identified

by the green canister it uses. This, Type I filter assembly filters the oil by

having it pass through the felt element from the inside to the outside.

The

Type II rear timing cover was an updated system that featured a ‘blocked filter

by-pass valve’ and the filtration was manufactured by Tecalemit. This type rear

timing cover can be easily identified by the two ports that supply engine oil

to an oil cooler. The filter medium in this filter is paper and the oil passes

through from the outside through the paper into the centre of the element.

The

Type III rear timing cover is essentially the same as the Type II. The only

difference being that the oil galleries are larger and the oil cooler ports are

also larger. This version, obviously, does not require modification to match

those discussed for the pump and crankcase.

Described

here are the modifications to the Type II rear timing cover to match the other

modifications:

38. The

rear timing cover should be completely dismantled, that includes removal of the

blocked filter by-pass valve.

39. Great

care has to be adopted when opening out the oil galleries in the cover.

Figure 3: The oil galleries to be enlarged.

40. In

Figure 3. the galleries adjacent to the fixing setscrew holes should be opened

out to 8 mm diameter. To do this, carefully set the housing up on a drill press

table so that a drill the same size as the original oil gallery diameter,

mounted in the drill chuck, passes freely in and out of the gallery bore. This

drill should not bind as it travels down into the bore. Remove this drill and

insert an 8 mm drill to carefully bore the gallery.

NOTE:

Feed the drill slowly. Do not be tempted to increase the depth of the bore.

41. Repeat

this process with the drilling adjacent to the other fixing hole.

42. Set

the housing up on the table so that the large oil gallery can be drilled, using

the same procedure, as described in Step 40, to 11 mm diameter.

43. Using

a beam of light, check that the drilling process has not broken through the

gallery walls.

Figure 4: Larger diameter return from filter port.

43. Mount

the cover on the drill table so that the return, from oil cooler, port and

gallery can be drilled.

NOTE:

Drill the actual gallery out to 8 mm diameter using the same procedure as

described in Step 40. The drill for this operation may need to be of the

long-series type.

DO

NOT deepen this gallery.

44. Enlarge

the banjo bolt drilling so that a thread can be tapped for a 16 mm banjo bolt.

45. Inspect

the drilling with a beam of light to check if the drill has broken through the

gallery wall.

Figure 5: Showing the enlarged outlet port.

46. Mount

the cover on the drill press table so that the out, to oil cooler, port and

gallery can be enlarged.

The

thread should be the same as described in Step 44.

NOTE:

Take care when the drill breaks through into the horizontal gallery. Do not

drill deeper.

That

completes the oil gallery and port enlargement process. If there is an instance

of oil gallery break-through the outer wall should be built up using the aluminium

Tig-welding process. The welded gallery should then be carefully re-drilled to

clean up any weld that may have penetrated.

It is

not really advisable to modify the Type I (Vokes) oil filter housing, because

there is not a great amount of wall thickness to permit enlargement of the

galleries. It is best to restrict modification to the Type II rear timing cover

only. It is understood that these were fitted to engines with the PD prefix in

the serial number.

Oil Gallery Finish

There

is a train of thought that considers the finish of the oil galleries as being

of utmost importance. The gallery walls must be as smooth as possible and

without any burrs that could be dislodged. Hence the call for slow feeding of

the drill during the drilling operation.

Another

consideration that is deemed important is that of the gallery end profile. It

is judged that the gallery end should be finished with a radiused-end cutter in

favour of the normal drill cutting edge angle. This does require extra tooling,

but can be beneficial in terms of oil flow dynamics.

Modifying The Oil Transfer Pipe

Figure 6: Showing an installed oil transfer pipe.

In

most cases, with respect to the Javelin. the Type II rear timing cover is not

attached to an oil cooler. This installation requires the provision of an oil

transfer pipe as shown in Figure 6. There are several points to consider when

making up such a pipe:

a) If

the engine has been fitted with a Series III front timing cover. If so,

allowance must be provided to let the formed pipe clear the rear distributor

mounting lug on the timing cover.

b) The

breather pipe assembly may require careful bending to allow for the larger

diameter oil transfer pipe to clear it. See Figure 6.

Make

up the pipe as follows:

47. Use

the same diameter copper tube as for the oil pump delivery pipe.

48. Use

the same banjo fittings (Figure 2.) as for the oil pump delivery pipe.

49. Cut

the hose barbs off the banjo fittings and drill out inlet ports to 11 mm

diameter. Clean up any burrs that may be present.

50. Mount

the banjo fittings on the rear timing cover ports with banjo bolts and sealing

washers.

Make

sure that the top fitting exits towards the RHS, but angled towards the rear

slightly.

Make

sure that the side mounted fitting exits towards the top, but is also angled

slightly towards the rear.

51. Form

the copper tube so that it forms a graceful curve rearwards and sits over the

bosses on the banjo fittings.

NOTE:

Make sure that the oil transfer pipe will not foul the engine oil filter

canister. See figure 6.

52. Silver

solder the joints so that they are strong and oil tight. Test with compressed

air, while the pipe is immersed in water.

53. For

appearance, the oil transfer pipe can be polished and treated with a clear

lacquer.

Installing The Modified Components

54. Measure

the oil passage holes in the banjo bolts and enlarge to provide the same, in

total, cross sectional area as the pipe work they are used for. Enlarge these

holes if possible.

55. Wash

and air-dry all components before assembling to the engine. Make sure that the

blocked oil filter by pass valve is in good condition

56. It

is a good idea to use 16 mm Dowty washers at all of the banjo fittings. A Dowty

washer features a lipped seal bonded to its inner diameter. These washers, used

on smooth surfaces, form an oil tight seal without requiring excessive torque

values at the banjo bolts. This is a particularly useful feature if the oil

passages in the banjo bolts have been enlarged.

Testing The Oil Pump

The

oil pump can be tested and adjusted as follows:

57 Mount

the oil pump assembly on to a suitable test stand.

58. Connect

the delivery pipe to an oil pressure gauge.

59. Fill

a tub with SAE 30 engine oil, so that it fully covers the intake filter

housing.

60. Use

a cut off end of a distributor drive shaft set in the chuck of a reversible

electric drill. The drill should, ideally, be of the variable speed type.

61. Set

the drill speed to high ratio, and to run in anti-clockwise direction.

Figure 7: Oil pump test rig.

62. Hold

the drill firmly, but with some flexibility, so that once the speed is

increased the drill assumes, in the hands, a steady attitude and does not try

to orbit. Gradually bring up the speed until the drill is operating at maximum

speed.

NOTE:

This is were it gets messy. As oil is sucked in and delivered under pressure, there

will be jets of oil at the delivery elbow and from the top of the idler element

spindle. These jets are there to lubricate the timing chain and the oil pump

drive gear.

The

latest version of the test rig has built in deflectors to direct the jets back

into the oil container.

Figure 8: Showing the electric drill drive.

63. The

oil pressure should read 60 – 75 psi. If the pressure is low, it can be

increased by installing shims under the spring. Such shims are not a stocked

item, and therefore will need to be made.

If

the pressure is too high, a small portion of the spring can be ground off

carefully.

Setting

the pressure is a trial and error procedure.

64. If

the pump cover features an adjustable release valve – screw the adjuster

inwards to increase pressure, and outwards to decrease the pressure. Lock up

the jam nut each time an adjustment is made. Recheck the pressure each time.

65. Hang

up the oil pump and allow it to drain completely

66. It

should be noted that 2,000 rpm at the drill represents 4,000 crankshaft rpm.

Further Illustrations

Figure 9: Comparison of larger banjo bolt.

Figure 10: Shows difference in bore size.

Figure 11: Illustrates built up pump body.

Figure 12: Illustrates difference in delivery pipes.

Note

the smooth bend of the copper tube and how it fits over the banjo fitting and

the delivery elbow.

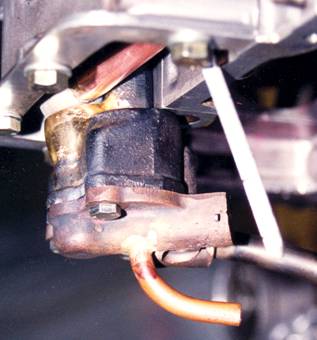

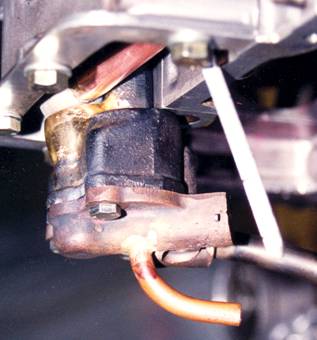

Figure 13: The modified oil pump assembly

Note the larger diameter pick up pipe and the oil return elbow. The

added material to the pump body can just be seen at left.

Figure 14: Trial assembly to a crankcase set.

Figure 15: Return elbow position.

Note that the elbow exits well below the bottom of the dipstick.