PART ONE:

WORKING

PRINCIPLES

Application

The Laycock de Normanville 'Overdrive' with

Lucas Ele-ctrical Control is now being applied to an increasing number of

British Cars.

The vehicles which come to mind at once

are:

The Austin Healey – 100, The Standard

Vanguard, Triumph Roadster and Renown, Rover 90, 100 and 105, Jaguar Mark VII –

XK 140, Triumph TR2, Bristol 405, Vauxhall Velox and Wyvern, Sunbeam Alpine

Special and Mk III, Humber Hawk Mk VI, Ford Zephyr and Consul, Swallow Doretti.

For those of us who are unfamiliar with the

overdrive, we shall explain the general functioning of the equipment and its

electrical control.

The Overdrive

On The Car

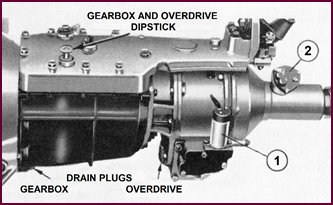

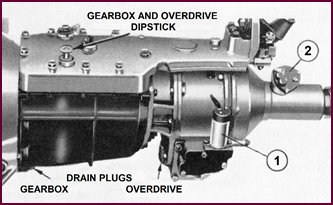

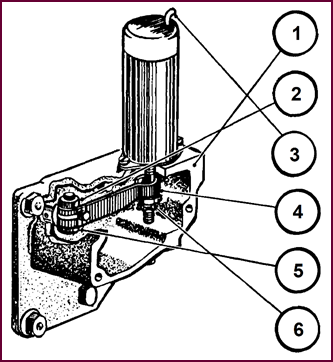

Figure 1 shows the

'overdrive' Gear Box in place behind the normal gearbox. Two of the major electrical

components are visible, the Main Operating Solenoid low down on the side '1'

and the Centrifugal Switch mounted on top at the back of the gear box at point '2'.

Figure 1 shows the

'overdrive' Gear Box in place behind the normal gearbox. Two of the major electrical

components are visible, the Main Operating Solenoid low down on the side '1'

and the Centrifugal Switch mounted on top at the back of the gear box at point '2'.

Figure 1. An overdrive unit on a gearbox

with two of the electrical components labelled.

To give some general idea as to how this

equipment works we cannot do better than briefly run over the manufacturer's

own description of it.

As will be generally realised, a motor car

engine depends partly for its power development on the number of revolutions

per minute, hence the provision of inter-mediate gears enabling the engine to

revolve at higher. revolutions for a given road speed, and so provide the ad-ditional

power required for acceleration and hill climbing.

In direct or top gear the only

multiplication of engine revolutions in terms of the driving road wheels is

through the rear axle, in which the crown wheel and pinion provide a reduction

ratio to suit the particular vehicle.

Considerations of engine power available,

the weight of the vehicle, wind resistance and other factors, determine the

actual ratios and top gear performance.

The direct top gear, whilst providing for

high cruising speeds must remain sufficiently flexible to avoid frequent gear

changes at lower road speeds.

It will be appreciated therefore, that the

selection of such an axle ratio must be something of a compromise. To provide

for flexible top gear performance at lower speeds, something must be sacrificed

at the maximum. In other words, the engine revolves faster than is actually

neces-sary at higher speed.

A means of overcoming this problem is to

over-gear, or 'overdrive' the speed of the propeller shaft, and thus the road

wheels, in relation to engine revolutions, or, vice versa, to reduce the speed

of the engine in relation to the road speed.

A very high top gear, possibly a fifth,

could be incorporated in the ordinary gearbox. With such a gear, however, it

would then be necessary to make far more frequent use of clutch, accelerator

and gear lever to engage the next lower gear in order to meet any sudden power

demand.

Road Speed

Comparisons

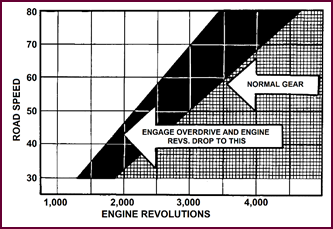

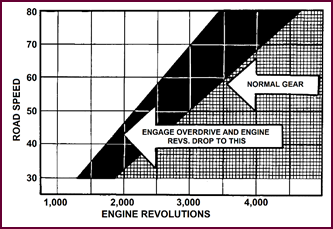

This diagram shows a typical example of engine speeds

in top gear and overdrive in relation to road speed.

This diagram shows a typical example of engine speeds

in top gear and overdrive in relation to road speed.

Figure 2. Diagram of road speed

comparisons.

The vertical ordinate of the graph shows

road speed, and the horizontal, engine revolutions. The cross hatched area

shows the comparative road speeds and engine revolutions in normal gear, and

the solid black section makes the same comparison with the car in overdrive.

Let us take one example – that of 3,000

engine revolut-ions which you will see on the bottom line. If you carry your

eye up to the inter-section of the hatched area and the black you will see that

at 3,000 engine revolutions in normal gear we have a road speed of 50 miles per

hour, with a corresponding road speed of 70 miles an hour when in overdrive at

the same engine speed.

Conversely, if we take a road speed of 50

miles an hour it will be seen that in normal gear the engine is doing something

over 2,000 revolutions for the same road speed. We should therefore, anticipate

a substantial improvement in petrol economy in overdrive.

Principle Of

Operation

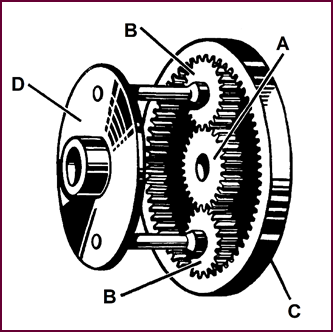

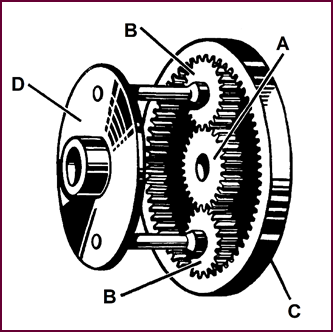

Basically the 'Overdrive' consists of an

epicyclic gear train, which comprises a SUN wheel 'A', a pair of PLANET Wheels 'B'

mounted on a PLANET CARRIER 'D', and an ANNULUS or outer ring 'C' – as shown in

Figure 3.

If the planet carrier is rotated whilst the sun

wheel is locked to the annulus or the planet carrier, the whole gear train will

rotate as a solid unit giving a direct through drive.

If the planet carrier is rotated whilst the sun

wheel is locked to the annulus or the planet carrier, the whole gear train will

rotate as a solid unit giving a direct through drive.

Figure 3. The epicyclic gear assembly.

If on the other hand, the sun wheel is

locked preventing it from rotating, and the planet carrier is turned, the

annulus will be overdriven at a higher speed

than the planet carrier.

How It Works –

Direct Drive

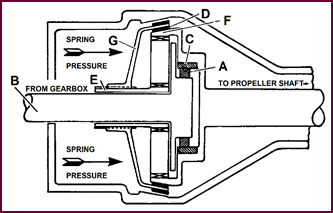

In addition to an epicyclic gear train similar to the

one depicted in Figure 3, there is also a hydraulic pump, a hydraulic

accumulator or pressure storage chamber, a roller clutch and a sliding cone clutch.

In addition to an epicyclic gear train similar to the

one depicted in Figure 3, there is also a hydraulic pump, a hydraulic

accumulator or pressure storage chamber, a roller clutch and a sliding cone clutch.

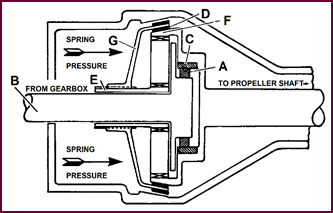

Figure 4. Schematic of direct drive –

top gear.

When in direct gear the overdrive is

inoperative. The drive is taken from the driving shaft 'B' through the rollers 'A'

of the roller clutch (or sprag clutch) to the annulus 'C'. It will be realised

that the roller clutch, being uni-directional can transfer power in one

direction only, and that if the car were to over-run the engine, the roller

clutch would act as a free wheel leaving the car without engine resistance to

assist braking. It would also be impossible to reverse the car for the same

reason. This problem is overcome by means of the cone clutch member 'G' which

slides on a splined extension 'E' on the sun wheel and is pushed by eight compression

springs so that the inner lining 'D' engages with the corresponding cone on the outer rim of the annulus 'F'.

This therefore, locks the sun wheel to annulus so that the entire gear train

and cone clutch rotate as a solid unit with the drive being taken through the

roller clutch, and overrun and reverse being taken through the cone clutch.

With Overdrive

Engaged

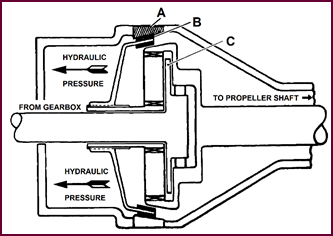

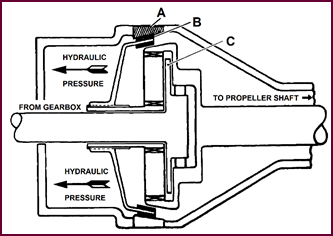

When the overdrive is engaged, a valve in the unit

is opened, applying hydraulic pressure from the pressure accumulator to two pistons which work in cylinders

formed in the unit housing. These pistons exert pressure against the

cone clutch member, overcoming the spring pressure and pushing the cone clutch

away from the annulus until the outer lining 'B' presses against a conical

brake ring 'A' built into the main casing of the gear box.

When the overdrive is engaged, a valve in the unit

is opened, applying hydraulic pressure from the pressure accumulator to two pistons which work in cylinders

formed in the unit housing. These pistons exert pressure against the

cone clutch member, overcoming the spring pressure and pushing the cone clutch

away from the annulus until the outer lining 'B' presses against a conical

brake ring 'A' built into the main casing of the gear box.

Figure 5. Schematic of overdrive

engaged.

The sun wheel, which carries on its splined

extension the cone clutch, is free to rotate on the driving shaft, there-fore,

when the cone clutch comes into contact with the brake ring, both cone clutch

and sun wheel are brought to rest and held stationary. The planet carrier 'C'

which is splined to the driving shaft is driven round the stationary sun wheel

so that the planets rotate and overdrive the annulus at a higher speed than the

driving shaft.

In overdrive, the outer member of the

roller clutch over-runs the inner member. Engine braking is again provided by

the cone clutch which holds the sun wheel from rotating in either direction.

Method Of

Operation

The change into or out of overdrive is made

without effort, and with perfect smoothness,

only the rise or fall in engine note

being noticeable, with resultant increase or decrease in engine noise

and vibration.

The use of overdrive claims to provide

considerable fuel economy, at least 10 per cent dependent upon usage and

circumstances, with additional saving in oil consumption and engine wear.

It is relevant to mention that the

overdrive gear may operate on top gear only, or on top and second gear, or top

and third – in a four speed box – as arranged in the original layout of the

vehicle.

There are also a variety of ways of

effecting the change into overdrive. One is direct through mechanical linkage,

the others with which we shall now concern ourselves are the electrical control

methods.

Electrical Control

Electrical Control

There are two forms of electrical control

in use, manual or automatic.

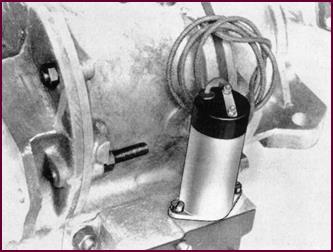

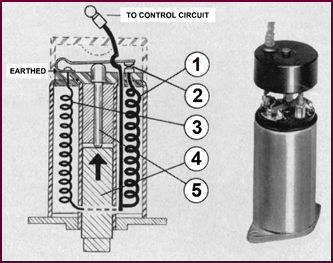

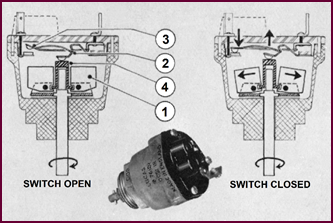

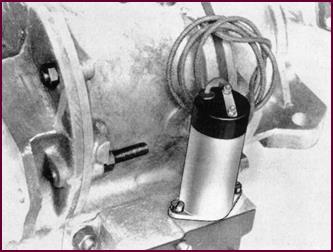

In either case, the principal unit is a solenoid switch,

which is featured in Figure 6, and is mounted on the side of the gear

box. Its function is simply to open and close the

hydraulic actuating valve for the overdrive gear change.

In either case, the principal unit is a solenoid switch,

which is featured in Figure 6, and is mounted on the side of the gear

box. Its function is simply to open and close the

hydraulic actuating valve for the overdrive gear change.

Figure 6. The Lucas TGS 1 overdrive

operating solenoid.

The various other components used on either

or both systems are concerned only with the control of this main solenoid.

We can now examine the simple form of

manually operated electrical control.

The Manually

Operated Electrical Control

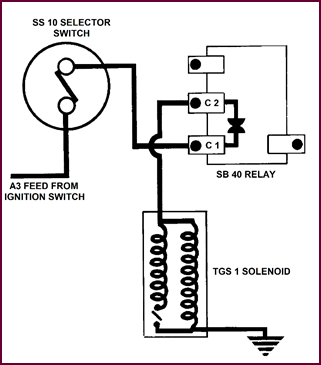

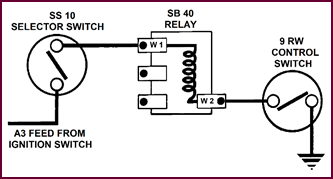

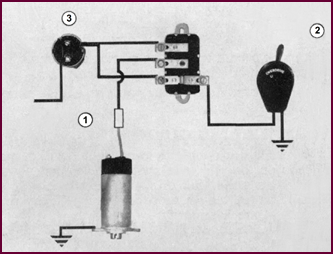

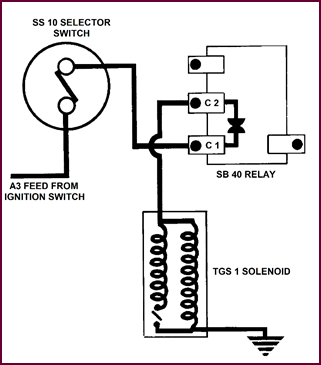

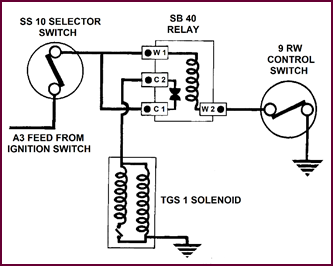

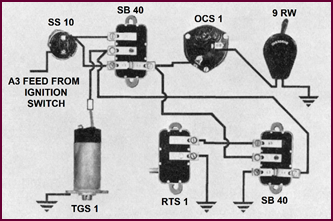

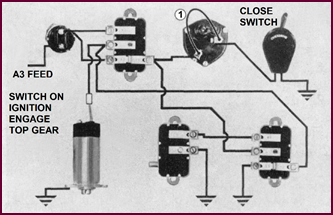

In this arrangement the main solenoid is

operated through a relay switch type SB40 which is itself actuated by two

separate switches.

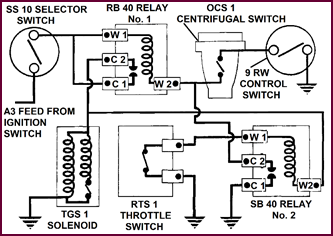

The current supply which is generally under the master

control of the ignition switch and is taken from the 'A3' terminal of the

ignition switch, is shown at the left of the circuit in Figure 7.

The current supply which is generally under the master

control of the ignition switch and is taken from the 'A3' terminal of the

ignition switch, is shown at the left of the circuit in Figure 7.

Figure 7.

Commencement – control switch circuit diagram.

A first requirement of the arrangement is

that the over-drive must not operate in reverse gear or in the first or first

and second gear of the 3 or 4 speed gearboxes respectively. The current supply

is therefore taken direct to a plunger type switch SS10 as shown on the left of

the diagram, which may be installed in the side of the gear box, or

alternatively linked to the gear change mechanism and operated by the gear

selector lever. This switch ensures that the circuit for the overdrive solenoid

is never complete unless the correct gear is selected.

Figure 8. The circuit diagram from the

relay to the over-drive operating solenoid.

From the other side of this switch the

current is fed via terminals W1 and W2 of the relay windings through a

simple ON-OFF switch to earth.

The comparatively heavy current required to

operate the Solenoid itself, is switched by the main contacts of the relay at terminals C1 and C2. This current supply

provides a feed for both windings in the solenoid which are earthed. We

shall be dealing more fully with these 'Main' and 'Hold-on' windings later on.

Electric Manual

Control

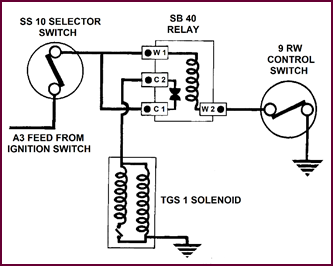

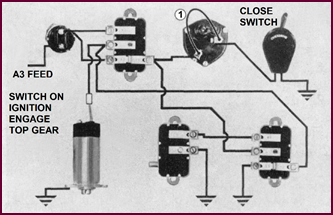

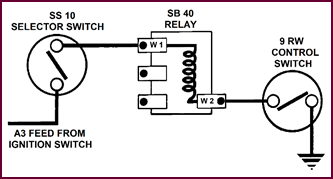

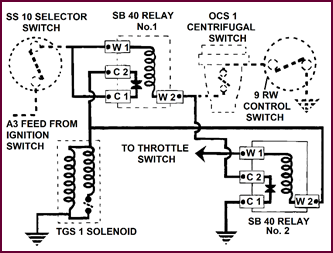

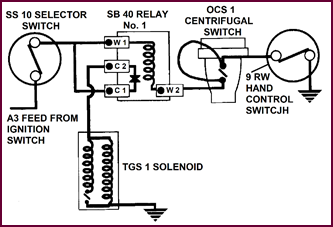

In Figure 9 we have the complete circuit for the

electric-ally operated manual control.

In Figure 9 we have the complete circuit for the

electric-ally operated manual control.

Figure 9. Complete circuit for manual

electric control.

To allow the overdrive to become operative,

the hand control switch 9 RW shown on the right of the diagram, must first be

closed.

When top or the other prescribed gears are engaged, the

selector switch SS 10 will then also be closed, and current can pass through

the relay windings W1 and W2 to earth.

When top or the other prescribed gears are engaged, the

selector switch SS 10 will then also be closed, and current can pass through

the relay windings W1 and W2 to earth.

The Relay will then close contact C1 and

C2, allowing current to flow through the solenoid windings to earth; the

solenoid plunger will then lift and open the hydraulic valve which will engage

the overdrive gear, and it will remain engaged until either of the two switches

are re-opened.

The current supply to C1 terminal of the

relay is often taken direct from ammeter or main battery fuse.

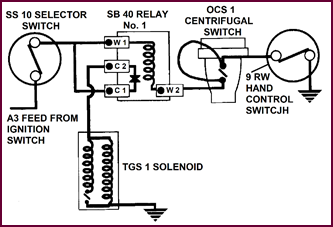

The Automatically Operated Electrical Control

We can now deal with the Automatically Operated Elec-trical

Control.

We can now deal with the Automatically Operated Elec-trical

Control.

Figure 10. Circuit diagram illustrating

the automatically operated electrical control of the overdrive.

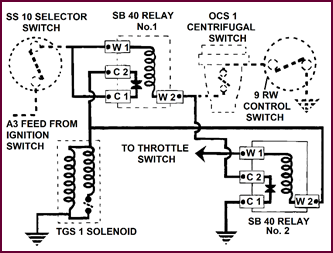

To achieve automatic changing into and out

of overdrive it is necessary to install firstly, a centrifugal or governor type

of switch which is driven from an extension of the Speedometer Drive Spindle.

In this component a single pair of contacts

are opened and closed by a governor at pre-arranged road speeds. In general

terms the governor closes the switch contacts at about 40 miles per hour (64

kilometres per hour) and opens them at between 30 to 35 miles per hour (48 to

56 kilometres per hour).

As shown in our picture this switch is

placed in the circuit between the W2 terminal of the No. 1 relay and the hand

control switch.

Thus, with the hand control switch in the

CLOSED position, the governor switch will operate the relay and engage and

disengage automatically. That is:

Change into

overdrive at about 40 miles an hour and;

Change back to

normal at about 30 miles an hour.

The centrifugal switch by itself will not

fulfil all the requirements, and it is necessary to introduce a further relay

operated by means of a switch linked to the accelerator pedal which we can now

consider.

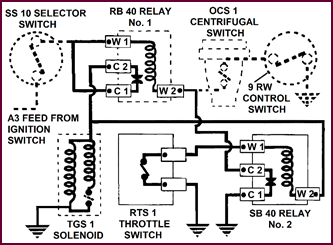

Light Running

Conditions

When coasting at small throttle openings,

even at speeds below 30 miles per hour – when the centrifugal switch will be

open – it is not desirable to come out of overdrive unless it is required to accelerate

sharply, when the throttle will be opened up.

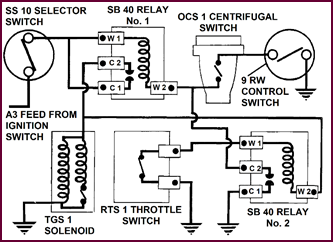

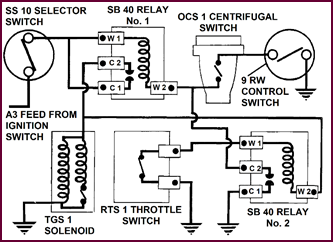

So, in order to keep the gear in 'overdrive'

under this Light Running Condition, a throttle switch linked to the accel-erator

pedal, together with an additional relay is introdu-ced. We shall refer to this

second relay, shown at the bottom right of Figure 11, as No. 2 relay.

Figure 11. Wiring circuit for light

running conditions.

The No. 2 Relay connected as shown – serves

to keep the No. 1 relay points CLOSED after the centrifugal switch contacts

have been opened. This No. 2 Relay will be energised when the throttle switch

is CLOSED, but as soon as the throttle switch is opened, the earth side of the

relay circuit is broken thus allowing the gear to change back to normal.

In brief, with the carburettor butterfly

and the THROTTLE SWITCH closed, the car will remain in overdrive.

With the throttle more than one fifth open

the switch will also be open and the car will return to normal gear until the

centrifugal switch contacts again close and changes it back into overdrive.

Figure 11 shows quite simply how the No. 2 relay

is added and connected to the No. 1 relay already in the circuit.

The No. 2 Relay And The

Throttle Switch

The No. 2 Relay And The

Throttle Switch

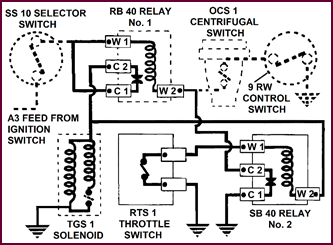

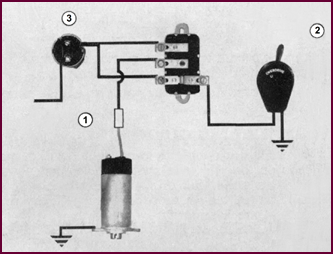

Figure 12. At lower right of the circuit

diagram are the added throttle switch and the No. 2 SB 40 relay.

Figure 12

shows the throttle switch added to the No. 2, relay and how the relay is placed

in the circuit.

Now try to follow this circuit through: the

conditions are that the car is run in overdrive at less than 30 miles per hour

with the gear selector and the control switches closed, and the centrifugal

switch open.

For this condition current is fed from the

C2 main contact of the No. 1 relay direct to the W2 terminal of the No. 2

relay, as shown at the bottom right, through the windings to W1 and thence across

the contacts of the throttle switch to earth.

In this condition the No. 2 relay is

energised, the contacts C1 and C2 will be closed, thus keeping the No. 1 relay

energised, and the hold-on current for the main operating solenoid will be

maintained irrespective of the centrifugal switch being open.

This condition will remain until such time

as the throttle is opened and the throttle switch contacts also opened, thus

breaking the current supply to the solenoid when the overdrive will change back

to normal drive.

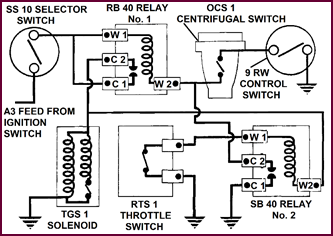

Automatic

Operation

Here we have the complete circuit of the automatic control

which you may wish to study before commencing on the next part.

Here we have the complete circuit of the automatic control

which you may wish to study before commencing on the next part.

Figure 13. The complete circuit for

automatic operation.

PART TWO: DESCRIPTION OF OVER-DRIVE CONTROL UNITS

The Electrical

Components

So far, we have built-up our overdrive

control, using the following components:

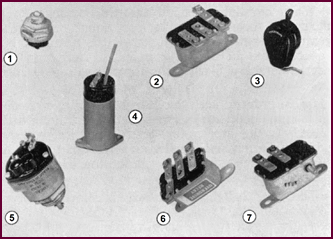

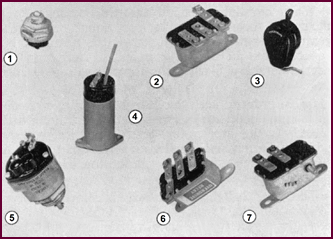

Commencing at the top left of the picture

for the 'Manual Control' System there are four units.

1. The Gear Selector Switch, type SS10.

2. The Relay type SB40 Relay.

3. The 'Hand' or 'Overdrive' Control Switch type 9RW.

4. The 'Transmission Gear Solenoid' type TGS1.

For 'Automatic' Control there are three

additional units :

5. The 'Centrifugal' Switch type OCS1.

6. An additional SB40 Relay.

7. The Rotary Throttle Switch type RTS1.

You will remember that the various switches

exist only to make the No. 1 Relay actuate the transmission gear solenoid under

differing conditions, and that this solenoid opens the hydraulic valve in order

to change the gears from 'Normal' to 'Overdrive' and vice versa.

We can now examine these components individually.

We can now examine these components individually.

Figure 14. Individual components

supplied by Lucas for the control of an overdrive.

Gear Selector

Switch Type SS10

As previously mentioned this switch is usually the first

component in the current supply line and may be installed in the side of the

gear box.

As previously mentioned this switch is usually the first

component in the current supply line and may be installed in the side of the

gear box.

Figure 15. The gear selector switch.

Its function is to keep the overdrive gear

out of engage-ment, generally, in first and reverse gears.

In construction it is a simple ON-OFF

Plunger type switch. It is not a diaphragm switch and it is not oil proof.

At the same time oil passing through it

will not generally affect its operation.

Service troubles with this switch are

mostly due to incorrect setting of the external linkage, not providing sufficient

plunger travel to properly close the contacts.

It can easily be tested on or off the

vehicle by means of a Voltmeter or Lamp bulb across the contacts.

With Plunger

'out' switch should be open.

With Plunger

'down' the switch is closed.

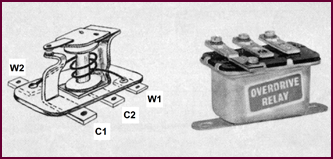

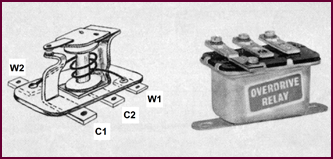

Type SB40 Relays

You may be aware that the general function of a relay

switch is to enable a current, particularly a fairly heavy current, to be switched

'on or off' from a remote position, thus minimising the voltage loss, generally

termed 'Volt Drop', which may occur.

You may be aware that the general function of a relay

switch is to enable a current, particularly a fairly heavy current, to be switched

'on or off' from a remote position, thus minimising the voltage loss, generally

termed 'Volt Drop', which may occur.

Figure 16. The Lucas SB40 relay.

The SB40 relay shown is a typical example

of this class of switch.

The main current supply is connected at the

C1 and C2 terminals, and terminates at the contact points as shown.

When the armature is drawn down on to the bobbin

core, the points close allowing a current to pass.

Terminals W2 and W1 are connected to the

ends of the relay coil winding as shown. A quite small current passing through

this winding creates a strong magnetic field in the core and pulls down the

armature, and so closes the main contacts which will remain closed for as long

as the relay coil is energised.

This model of the SB40 has been built

specially for the overdrive and the label 'Overdrive Relay' distinguishes it

from the model SB40 generally used as a horn relay, which is not suitable for

the overdrive, the main difference being that one is designed for continuous

working and the other for intermittent service only. Both the SB40 Relays used

on the overdrive are identical and interchangeable.

Normally these relays are practically

foolproof other than when the points become overheated and damaged, as may

result from an external short circuit.

They can be proved by two very simple

continuity tests.

1. For the Relay Windings.

2. To check continuity under load across the main contacts.

The Overdrive

Control Switch

Figure

17. A control switch for the overdrive.

This is a plain ON-OFF Switch, lever

actuated, and may be of various patterns according to the mounting position,

which is generally on the steering column or facia panel.

The

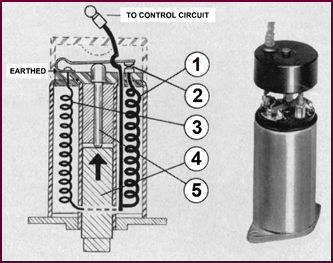

Transmission Gear Solenoid

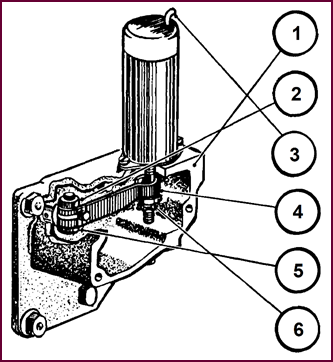

The transmission Gear Solenoid when energised is the

unit which brings about the change into and out of over-drive. As shown in Figure

18, the solenoid itself has two windings. A heavy, or closing winding shown

on the right '1', connected to EARTH through a pair of contacts '2'.

The transmission Gear Solenoid when energised is the

unit which brings about the change into and out of over-drive. As shown in Figure

18, the solenoid itself has two windings. A heavy, or closing winding shown

on the right '1', connected to EARTH through a pair of contacts '2'.

Figure 18. The Lucas TGS1 solenoid.

The hold-on winding is connected directly

to earth '3', as shown on the left. Both of these windings are in circuit when

the current is applied.

When the solenoid plunger '4' is pulled

into the coil the end of the plunger lifts the striker pin '5', and opens the

main winding contacts '2'. These contacts remain open whilst the plunger is in

the raised position thus keeping the main winding open circuited.

The heavy or closing winding requires 18 to

19 ampéres and is only in

circuit momentarily.

The hold-on-winding requires about 1 to 1·5

ampéres and is sufficiently

powerful to hold-up the Solenoid Plunger indefinitely. Point clearance and Air

gaps are pre-set and cannot be altered in service.

It will be realised at once that the

ingress of metal, dust, dirt, water or oil into the solenoid assembly can seriously

interfere with its operation and in the event of failure of this unit, wholly

or in part, this is the first thing to look for.

Transmission

Gear Solenoid Attachment – The Hydraulic Actuating Valve

We next come to the attachment and set-up

of the trans-mission gear solenoid to the gear box itself.

To ensure satisfactory operation, it is

necessary that the set-up of the solenoid to the gearbox is correct, and in the

event of trouble or during a re-setting operation this is the first thing to

check.

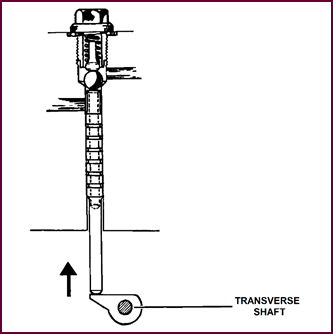

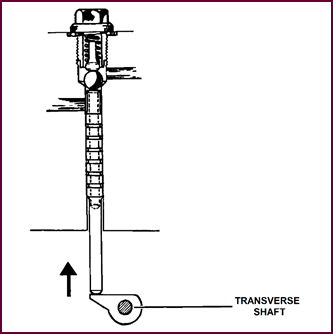

The Hydraulic Valve shown Figure 19

is actuated by a cam fixed to a transverse shaft running through the gearbox.

The Solenoid plunger operates through a lever attached to the other end of this

shaft. When the solenoid is operated this valve must be fully opened.

The Valve

Setting Lever

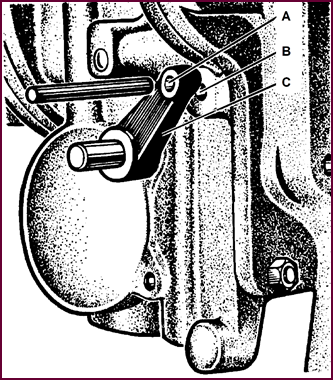

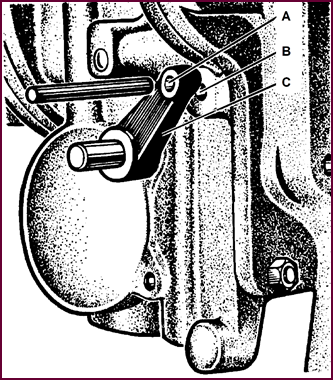

With the solenoid energised, the setting of this valve

can be easily checked at the offside of the gearbox shown in Figure 20.

With the solenoid energised, the setting of this valve

can be easily checked at the offside of the gearbox shown in Figure 20.

Figure 19.

Operation of hydraulic valve by solenoid TGS1.

The end of the valve actuating shaft carries a short

lever 'C' with a 3/16" (4·76 mm) diameter hole

at the outer end, which should register with a similar hole in the casting as shown

at 'A' and 'B' (Figure 20). If it does so the valve setting is correct.

The end of the valve actuating shaft carries a short

lever 'C' with a 3/16" (4·76 mm) diameter hole

at the outer end, which should register with a similar hole in the casting as shown

at 'A' and 'B' (Figure 20). If it does so the valve setting is correct.

Figure 20. Checking the valve setting.

For the purpose of setting the solenoid

plunger – which we shall deal with later - a 3/16"

pin such as a drill shank – will be inserted to hold the valve in its correct

open position whilst setting the solenoid lever at the other side of the

gearbox.

The Replacement

Of The Transmission Gear Solenoid

If for any reason the solenoid has to be changed, the

original Plunger may be left in position provided that it is clean and free

from rust.

If for any reason the solenoid has to be changed, the

original Plunger may be left in position provided that it is clean and free

from rust.

Figure 21.

Replacement of the transmission gear solenoid.

In this circumstance it will be necessary

to check the setting for correct valve operation after fitting the new solenoid. To do this the following operations are

necessary:

1. Energise the solenoid.

2 Check the position of the valve setting lever, on the offside of

the overdrive unit, by inserting the 3/16" pin and if the holes

will not line-up the solenoid assem-bly must be re-set.

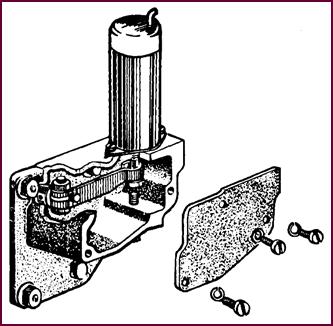

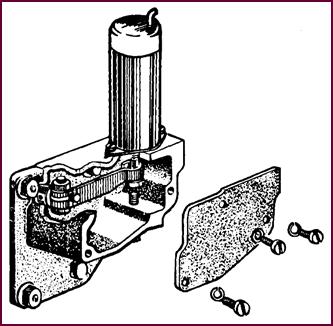

The Setting Of The Transmission Gear Solenoid

A complete re-set of the Solenoid assembly

is carried out in the following manner, Figure 22 refers.

Commencing with the 3/16"

pin in position (Figure 20) on the valve setting lever to hold the valve

open proceed to:

Remove the cover

plate '1'.

Loosen the lever

clamping bolt '2'.

Energise the

solenoid '3' (Check that the plunger travels the full movement).

Hold the lever

lightly against the plunger bolt head '4'.

Re-tighten the

lever clamping bolt '5' taking care to see that there is no end play in the

cross shaft.

Check the REST stop

clearance to ¼" (6·35 mm) '6'.

Remove the

locating pin from the offside of the gearbox.

Operate the

solenoid several times to check for correct working.

Note: A simple way to energise the solenoid

is to break the snap connector at the Solenoid terminal and connect with a

short lead direct to battery negative.

Figure 22. Setting the transmission gear

solenoid

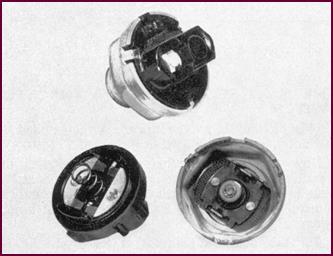

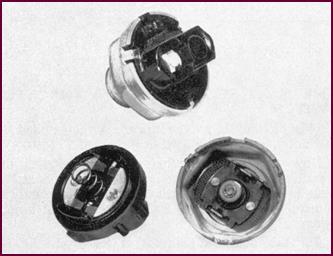

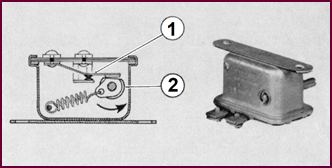

The Centrifugal

Switch

Figure 23. The centrifugal switch and its

operation.

Figure 23. The centrifugal switch and its

operation.

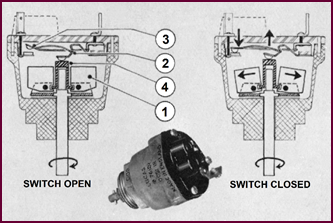

Driven from the speedometer take-off

spindle, this switch comprises two components:

An orthodox type

of flyweight governor '1' actuating a plunger shown at '4'.

A micro switch

movement '2' opening and closing a single pair of contact points, shown at '3'.

Increasing speed throws the weights

outwards and lifts the plunger, which in turn closes the micro switch con-tacts.

Thus switching ON the current to the Overdrive solenoid through the No. 1

Relay.

The points close at round about 800

governor r.p.m. This speed is pre-set and varies according to the model of

vehicle.

With falling speed, the points re-open at

80 per cent of the closing speed.

In practice this means that the vehicle generally changes

to overdrive around the 40 miles per hour (64 kph) mark and returns to normal

gear round about 30 to 35 miles per hour (48 to 56 kph).

In practice this means that the vehicle generally changes

to overdrive around the 40 miles per hour (64 kph) mark and returns to normal

gear round about 30 to 35 miles per hour (48 to 56 kph).

A figure giving the closing revolutions of

the switch is stamped on one of the flats of the hexagon body.

If trouble is experienced in service,

several points can be looked to:

Damaged or loose

terminals which may result from contact with any external obstruction and may cause

erratic operation.

Terminals becoming

intermittently earthed, due to contact with the tunnel casing.

After removal of

the switch, check that it is being driven and for possible end float at the

spindle.

This should be about

0·002" and may cause erratic operation if excessive.

A further cause

of erratic running may also result from excessive vibration at the gear box

itself which the fitting of a replacement switch will not generally overcome.

These switches

are all pre-set at the works and must not be altered in situ. Also the

moulded top assembly should not be interchanged or the settings will be completely

upset.

The Rotary

Throttle Switch

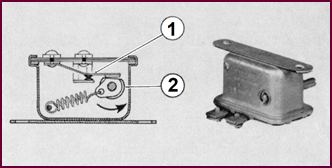

You will remember that the function of this

switch which is linked to the accelerator pedal, is to maintain current to the

overdrive solenoid by means of the No. 2 relay. This applies when the vehicle is running in top gear

below 30 miles per hour with the throttle CLOSED and the centrifugal switch

OPEN.

You will see in Figure 24 that the switch

comprises:

1. A pair of contacts on a spring blade.

2. A circular cam with a flat section, which is rotated by means of

a lever linked to the accelerator pedal. A spring is incorporated to return the

cam to its original position when the accelerator pedal is released.

With the throttle closed, the points will also be closed;

when the cam is rotated the points will open and remain so until the throttle

is again closed.

With the throttle closed, the points will also be closed;

when the cam is rotated the points will open and remain so until the throttle

is again closed.

Figure 24. The rotary throttle switch.

It is a simple matter to check this switch:

1. See that the points are opening and closing.

This can be done by means of a voltmeter, or a Test Lamp

connected in series with the two terminals.

2. See that the rotating cam is correctly timed to the accelerator

pedal.

The correct setting of the cam is as follow

:

Referring to the extreme right of the Figure

24, the screw-driver slot in the end of the shaft should be horizontal with

the switch in the rest position.

The total movement of the cam is 90° and the contacts should remain closed for

the first 15° to 35° of rotation.

The Complete

Automatic Control

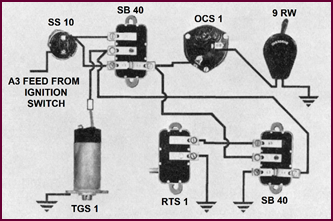

Finally, here is the pictorial diagram of the

complete Auto-matic Control from which it may be seen how simple the whole

arrangement is.

Finally, here is the pictorial diagram of the

complete Auto-matic Control from which it may be seen how simple the whole

arrangement is.

Figure 25.

The complete automatic control of the overdrive.

Legend:

SS 10 Selector Switch

SB 40 Relay No. 1

OCS 1 Centrifugal Switch

9 RW Manual Control Switch

TGS 1 Transmission Gear Solenoid

RTS 1 Rotary Throttle Switch

SB 40 Relay No. 2

You may perhaps like to study this and make

a copy of it for future reference.

PART THREE:

TESTING

Testing On The

Vehicle

Checking and testing of this equipment in situ

on the vehicle may be simply and easily carried out if the follow-ing

instructions are carefully followed when any defective unit or wiring will

show-up.

A quick overall test can be carried out

almost in a single operation without any special tools.

A full diagnosis test can be done with a

simple test volt-meter and ammeter.

Fault Finding

Guide

We shall deal primarily with faults which

may develop on the vehicle in service. The chart shown here lays out the kind

of symptoms which may be met and, as you will see, those concerning the

electrical equipment are a minority.

From the chart it will be seen that there

are five main items:

No. 1. Overdrive

Does Not Engage

Electrically this may be due to the

solenoid operating lever adjustment or any other electrical defect.

No.2. Overdrive

Does Not Release

Electrically this may also be due to

incorrect solenoid plunger and operating lever adjustment, or some other

electrical defect.

No.3. Clutch

Slips In Overdrive

Again this may be due to incorrect

adjustment of the solenoid operating lever.

No. 4. Clutch Slip

In Reverse Or Free-wheel Condition In Overdrive

As auto-electricians we are not concerned.

No. 5. Overdrive Engages

Overdrive engages in the normal manner but

when the Throttle is CLOSED should the speed drop below that at which the

centrifugal switch contacts open a return to normal gear accompanied by a heavy

braking effect, occurs.

This trouble will be primarily due to

incorrect setting of the throttle switch lever, or it might be a faulty No. 2

relay.

The test routine that we shall specify will

cover in a few simple operations anything that can happen to the electri-cal equipment

under all of the headings shown, which is all that the electrician is concerned

with.

Fault Finding Chart

(Set Out Below)

Note: It appears that this procedure

chart has been taken from a vehicle manufacturer's service manual for a car

model equipped with an overdrive unit. That is why, very likely, there are

non-electrical procedures shown here. These are shown in blue text, black text

is Lucas content.

No. 1 – Overdrive Does Not Engage

Insufficient oil in

unit.

Check solenoid operating lever adjustment. Check

the electrical system.

Check operating valve.

No oil pressure.

No. 2 – Overdrive Does Not Release

Check operating

valve.

Check electrical system.

Check solenoid plunger and operating lever

adjustment.

Check for sticking

cone clutch.

No. 3 – Clutch Slips In Overdrive

Check oil in unit.

Check solenoid operating lever adjustment.

Check for low

hydraulic pressure.

No. 4 – Clutch Slip In Reverse Or Free

Wheel Con-dition In Overdrive

Check restriction in

valve jet causing sluggish operation of cone clutch.

NO. 5 – Overdrive Engages: With Throttle

Closed A Return To Normal Gear, With A Heavy Braking Effect, Occurs As Speed

Diminishes

Check for correct setting of rotary throttle

switch (RTS1) lever. Check electrical system.

Checking The Manually

Operated Electrical Control

Checking The Manually

Operated Electrical Control

Figure 26. Procedure for checking the

manually operated electric control.

Let us first deal with the hand operated

electrical control – the simpler of the two. Irrespective of any specific complaint

which may be made, a quick and simple overall test of workability can be

carried out in three operations, after removing the floor casing to gain

access:

1. Switch ON the ignition (Item 1, Figure 26l).

2. Close the hand control switch (Item 2) and engage top gear, thus

closing the gearbox selector switch contacts (Item 3).

If the system is working the solenoid will immediately operate

and open the hydraulic valve.

Check this visually by observing the movement of the valve

setting lever on the offside of the gearbox, when the two 3/16"

pin holes should register.

This proves immediately that:

The current

supply is on.

The gearbox

switch is closing properly.

The hand control

switch is closing properly.

The relay main

contacts and operating windings are both working.

That the main

solenoid is also operating.

Lastly, from an

observation of the valve setting lever we shall

know that the Hydraulic Valve is being fully opened.

Checking The

Automatic Control System

We can next apply a similar check to the automatic

system in four operations. With the vehicle stationary and the engine stopped,

proceed to:

Switch on the

ignition.

Close hand

control switch and engage top gear.

Link the

terminals of the centrifugal switch as shown at (Item 1, Figure 27).

Then:

If the system is

operative, the main solenoid will be raised and will remain in this position.

Check the correct

'Open' position of the valve setting lever on the offside of the gearbox.

This simple operation of linking the

terminals of the centrifugal switch proves:

1. The current supply is ON.

2. The gearbox switch is closing properly.

3. The hand control switch is closing.

4. That the main solenoid is operating.

5. That the hydraulic valve is opening fully.

If, when the link is removed, the solenoid plunger is still

held, we also prove:

6. The main contacts and relay winding of both relays are

operative.

7. That the throttle switch is closed.

7. That the throttle switch is closed.

Figure 27. Checking the automatic

control system.

Test Procedure

If the equipment fails to operate when the

foregoing checks have been carried out, it will be necessary to make a

methodical fault diagnosis.

This can most easily be done in three

stages:

Stage 1. The

circuit comprising – the SS10 switch, the hand control switch, the No. 1 relay

and the main solenoid.

Stage 2. The

circuit including the No. 2 relay and the throttle switch.

Stage 3. A

test for the centrifugal switch and the main solenoid.

This is equally applicable to the manual

circuit and represents the complete test for it.

Stage 1 Test

To Test the SS10, the Hand Control Switch,

the No. 1 Relay and the Main Solenoid.

(A)

This test is carried out in six operations

as follows:

With the engine stopped and the car

stationary. Switch on the ignition.

Select top gear, thus closing the SS 10

gearbox selector switch

Bridge the terminals of the centrifugal

switch (if automatic control).

Close the hand control switch. If the

current is normal the main solenoid will come into operation and remain in the

raised position.

Check the position of the valve setting lever

(off-side of the Gearbox).

Check the position of the valve setting lever

(off-side of the Gearbox).

Figure 28. Circuit diagram for Stage 1

test.

(B)

If the Solenoid fails to operate, proceed

to:

Break the snap connector at the Solenoid

and energise it repeatedly by means of a jump lead direct from the battery

negative terminal.

If the solenoid proves to be in order:

Open the hand control switch and check

through for full voltage readings with the negative voltmeter at the following

points:

Across both terminals of the SS10.

Between – W1, W2 and C1 terminals of the

No. 1 relay respectively and earth.

Between live side of the hand control

switch and earth.

Close hand control switch when the voltage

reading should fall to zero if the switch and earth line are in order.

The No. 1 Relay should then close and a

voltage reading should be obtained at Contact C2 (No. 1 relay) and also at the

end of the solenoid feed wire. If no voltage is obtained at C2, the relay is

defective.

Stage 2 Test

Stage 2 Test

Figure 29. Circuit diagram for Stage 2

test.

The part circuit, comprising the No. 2

relay and the throttle switch.

Still with the ignition switch on and top

gear engaged, remove the bridged lead from the centrifugal switch.

Link terminals C1 and C2, of the No. 2

relay when the solenoid should come into operation and remain in the raised

position.

If no operation when the C1 and 2 terminals

are linked, check relay No. 2 for a good earth connection to C1 terminal, or

for a broken wire between the W2 terminal of No. 1 relay and C2 terminal of No.

2 relay – put in order.

On the removal of the link between C1 and

C2 terminals after the solenoid has closed, the solenoid should remain raised

and return to normal rest position when the accel-erator pedal is depressed.

If, when removing the link, the solenoid

returns immed-iately to the rest position and does not hold, check the throttle

switch setting also link the C1 and C2 terminals again then with a voltmeter

check for a voltage at the W2 terminal of the No. 2 relay. If in order,

transfer the volt-meter lead to W1 terminal and with the throttle switch open

voltage will be registered if the relay winding is in good order and voltage

reading will disappear when the throttle switch is closed proving the switch

circuit is com-plete to earth.

If not put in order.

Stage 3 Test –

Control Switch And Solenoid

To check the operation of the Centrifugal

Switch and the solenoid.

Jack-up the back wheels.

Open the push-in connector adjacent to the

solenoid and insert the test ammeter in this line.

Start up the car and engage top gear.

Increase engine speed and the centrifugal

switch should close at slightly above 40 m.p.h. The main solenoid should then

close with a surge of current and the ammeter should remain at 1 to 1½ amps.

showing that the 'hold-on' coil is operative, and the main winding cutting out.

If a heavy current of about 20 amps registers continually, it will probably be

necessary to check the solenoid which will have become overheated.

Immediately check the valve setting lever

as shown on Page 9.

Document

Restorer's Note

Once again, the course session stresses

the requirement for good earthing contacts. This is particularly so when

carrying out the recommended tests.

Observe Domestic Science notions – keep

earth contacts clean and soundly tight.

Mike

Allfrey.

Jowett

Car Of Australia Inc.