The distributor performs a dual function. It forms part of the

primary circuit of the ignition system and determines when the sparks should

occur at the sparking plugs. It also forms part of the secondary circuit of the

ignition system and distributes high voltage to the sparking plugs in the

correct firing order.

An electronic distributor performs the same functions as a contact

breaker type distributor. The secondary circuit is similar, but the primary

circuit is quite different. An electronic distributor must be installed into a

Negative to Earth electrical system.

The electronic distributor that suits the Jowett installation is a

Toyodenso from a 1982 Honda Civic. For an optimum installation, some changes to

the distributor body and drive shaft are recommended. More detail on this later

on.

Electronic Ignition – Description

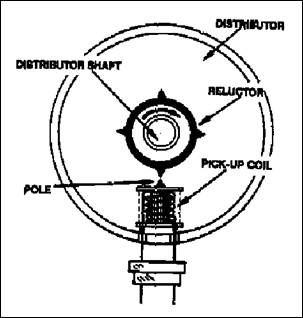

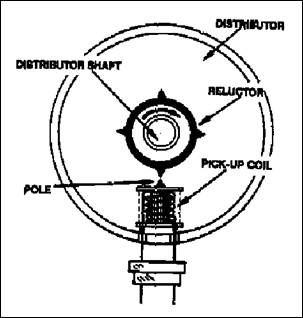

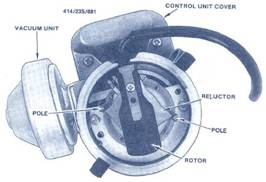

Above:

In electronic ignition, a pulse is generated each time a tooth of the reluctor

passes the pole of the pick-up coil.

Above:

In electronic ignition, a pulse is generated each time a tooth of the reluctor

passes the pole of the pick-up coil.

The distributor used with electronic ignition performs the same

functions as those performed by a contact breaker type distributor, but an

electronic sensor is used instead of 'make and break' points. The sensor

determines when a spark should occur and a transistor, used as a switching

device, breaks the ignition coil primary circuit to produce a high voltage for

the spark. The rotor and distributor cap perform the normal function of

distributing the voltage to the sparking plugs.

The sensor consists of a reluctor, or signal rotor on the

distributor shaft, and a pick-up coil on the distributor housing, which form a

pulse generator. As the distributor shaft rotates, teeth on the reluctor pass

the pole of the pick-up coil and a small electric pulse is generated each time

this occurs. The reluctor has one tooth for each cylinder of the engine.

The ignition system has an electronic control module, also called an

igniter, to which the pulse signal is directed. Whenever a pulse is received, a

transistor in the control module opens the primary circuit to produce a spark

from the ignition coil. The transistor is merely an electronic switch which

performs the same function as the 'make and break' points in a contact breaker

ignition system.

The pulse generator which has been briefly described, is known as an

inductive pulse generator.

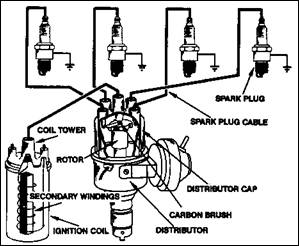

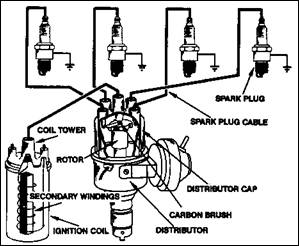

Above: The secondary

circuit produces a high voltage and distributes it to the sparking plugs.

The Secondary Circuit

The secondary circuit of the distributor is responsible for

distributing the high voltage produced in the ignition coil to the sparking

plugs. The distributor is fitted with a moulded plastic cap which carries the

high tension cables. The cable in the centre post in the cap is connected to

the ignition coil and this carries high voltage from the coil to the

distributor. The sparking plug cables are located around the cap in engine

firing order and connected to the sparking plugs.

The distributor cap is secured to the distributor housing with two

Allen head setscrews, and the cap is sealed against water ingress by a rubber

gasket.

The rotor arm, located inside the distributor on top of the

distributor drive shaft, rotates with the shaft to distribute high voltage to

each sparking plug cable post in turn. The high voltage produces a spark across

the electrodes of the sparking plug to ignite the air-fuel mixture in the

cylinder.

Engine Firing Order

The Jowett engine employs the firing order of 1-4-2-3. This firing

order is marked clearly on the motor car's chassis identification plate.

The distributor cap has an embossed '1' adjacent to the sparking

plug cable post for that cylinder. The rotor arm, when viewed from above,

rotates anti-clockwise and the other cables are connected in the continuing

firing order 4, 2, 3 from number one cable post.

Installing The Electronic Distributor

The Toyodenso TD-03D is, very likely, the most desirable distributor

specification. That model was not readily available, and a TD-03E was obtained,

therefore the advance characteristics were set to match the last Jowett Cars

Limited specification. At the same time the distributor was mechanically

overhauled.

The Toyodenso and Lucas distributor bodies are virtually identical.

However, the Toyodenso features a longer shank for mounting into the engine. As

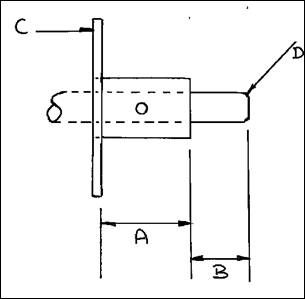

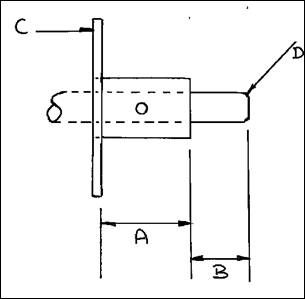

a result, the drive shaft is correspondingly longer. The sketch at right,

illustrates the dimensions that the Toyodenso unit can be modified to, so that

it can be installed directly into the Jowett engine.

The relevant dimensions (sketch not to scale) are as follows:

'A' 1.500"

(Length of distributor spigot)

'B' 1.00"

Length of shaft beyond spigot face)

'D' 0.125"

Radius

'C' Reference point, adjuster plate –

dimensions

taken from RH face

Item 'C' is the mounting plate, also known as the adjustment plate,

that is secured to the base of the distributor housing. A new plate was made

from 4 mm thick aluminium plate. Care needs to be taken when making the

adjustment plate, because its final shape has to be determined from whether the

engine's front timing cover has the adjuster plate lug aligned at right angles

to the engine centre line (earlier models with DKY type distributor), or, if

the cover has two lugs aligned parallel with the engine centreline (Series III

front timing cover for Lucas DM-2 type distributor). Start with a larger than required

flat plate, and mark out the hole for the distributor mounting spigot to pass

through. Next, mark out the hole for securing the adjuster plate to the

distributor housing. This hole is for a brass 5 mm diameter by 10 mm

countersunk head setscrew. With the adjuster plate attached to the base of the

distributor housing, mark out the curved slot in the plate, so that, when

installed, the distributor assembly will be free to pivot on the timing cover

flange. Make the slot of generous length, to provide plenty of adjustment when

setting the ignition timing.

At this stage it is a good idea to mount the distributor assembly to

check that, particularly on the Jupiter engine, there is generous clearance at

the water pump. The best position is with the vacuum unit facing towards the

rear. This positioning provides maximum swing of the distributor for ignition

timing adjustment purposes.

Once the adjustment slot position has been determined, and the slot

has been cut, the adjuster plate can be 'slimmed' to match the timing cover

flange, but still covers the two breather holes in the sides of the housing.

Timing The Electronic Distributor

Depending on whether the original distributor was a DKY type or a

DM-2 type, there will be a differing drive slot orientation at the oil pump

shaft. Essentially, this does not matter – a distributor with an unpinned drive

dog can be set in any position. It is important that the distributor shaft is

set so that the metal end of the rotor arm is pointing to number one cylinder

sparking plug cable post in the cap. This aligns the reluctor with the pick-up

pole. There is a thrust washer between the drive dog and the distributor

mounting spigot The Lucas drive dog should be a snug fit on the Toyodenso

shaft, make sure that it is just loose enough to let the drive shaft turn in it

when the rotor is turned. If it is very loose, find a better fitting drive dog,

or use a piece of Blue-tack to semi-glue it to the shaft. Set the engine to top

dead centre (TDC) on the firing stroke at number one cylinder. With the Jowett

drive shaft, Part Number 50882 attached to the dog by its circlip, carefully

install the assembly into the engine. Hold the housing in the position that was

determined to provide clearance at the water pump body. Gently rotate the rotor

arm, until the tongue of the drive shaft engages in the oil pump shaft

coupling. The distributor should drop into its home position. Carefully rotate

the rotor arm so that the distributor shaft slips in the drive dog, until the

metal end of the rotor arm is pointing at the cable post for number one

sparking plug.

Without disturbing the rotor arm or the drive dog on its shaft, lift

the distributor out of the engine, place the dog in a drill bench vee block and

drill through the dog and shaft with a 1/8" diameter drill. There should

be 0.002" to 0.005" end float at the distributor drive shaft after

the dog is pinned. Clean away any residual swarf and drive in a spring tension

pin, Part Number 50615 from club stock, making sure that the split side is

facing the direction of rotation.

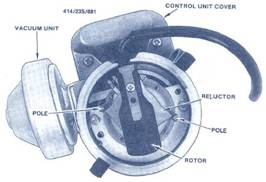

Above is shown a typical electronic distributor with the cap

removed. It is neither the Toyodenso TD-03D nor the TD-03E, but it ably

illustrates the main components of the electronic distributor.

Before tightening the adjuster plate securing screw, apply a drop of

Loctite Studloc 262 under the countersunk head of the setscrew. Fully tighten

the screw. Do not allow the Loctite liquid to migrate along the thread,

otherwise setscrew removal in future will be extremely difficult.

The distributor can then be installed, with the rotor arm pointing

directly at number one cable post; with the engine set to TDC firing on number

one cylinder. Lock the adjuster plate in this position and rotate the

crankshaft through two revolutions and recheck the timing again. If it is not quite

correct, slacken off the adjuster plate nut and rotate the distributor housing

until the reluctor points align with the poles in the body. Tighten the adjuster

plate nut.

The engine should start and run at this setting.

NOTE: It is important to be aware that, due to the electronic

ignition system’s characteristics, the use of a ‘cheap’ ignition timing light ,

there will be seen to be an advance of 44° to 48° degrees of

advance as the engine revs rise. There is no cause for alarm when such advance

is observed.

It is best to set the static timing and then adjust under road test

conditions as stated in the Jowett Maintenance Manual.

Ignition Control Module (Igniter)

The module connector has five pins, arranged as shown below:

Note: This view is from the cable side of connector (looking at male

portion of module). The cables are identified as follows:

Top

Row – Left Green, to distributor (green)

Top

Row – Centre Black/white double bands, to earth

Top

Row – Right Blue/brown bands, to coil, negative (–)

Lower

Row – Left Blue, to distributor (blue)

Lower

Row – Right Black/white, power supply to ignition system 12 volt

The ignition control module should be mounted

on a bracket, away from engine vibration and in a relatively cool area. On the

Jupiter, it was found that an angle bracket suspended from the RHS horn mounting

was ideal. Keep the cable away from the engine cooling fan.

Igniter Notes

Ignition modules (also called igniters) are sensitive

electronic components and require careful location, away from heat and moisture

to ensure optimum performance in the areas of Dwell Control, Primary Current

Control and Primary Induced Voltage Clamping. Efficient primary current / dwell

control is very important in order to get the most energy from the ignition

coil.

Insufficient current I dwell leads to Iow

ignition coil output resulting in difficult starting, breaking down under load

and misfiring at high rpm.

Excessive current dwell leads to

overheating of ignition coil and the ignition module, causing premature module

failure and possible damage to other vehicle components.

Excessive primary induced voltage

leads to possible damage to coil and modules as well as other components

connected to coil negative such as tachometers, security systems and LPG

safety switches and closed loop controllers.

Written by Tony George.

Compiled by Mike Allfrey.

January, 2006.